A reader writes:

I've got a couple of cats, had 'em for a couple of years. I have trouble motivating them to chase their toys, ping pong balls, etc - it works once or twice a week, but otherwise they just ignore it. So I've decided to bring out the big guns and get a laser pointer.

It seems they're much harder to get in Australia since all those airplane shenanigans, even though I hardly need a galactic-range pointer.

Was wondering if you had a suggestions for where to nab a laser pointer appropriate for kitteh?

Jack

It's still pretty easy to buy your basic button-cell keychain laser pointer from electronics stores here in Australia. I think there might have been a brief drought when the new Think Of The Children Or The Pilots Or the Puppies Or Something OMG JUST BE AFRAID EVERYONE law was passed, while the stores made sure that the humble cat toys they were selling yesterday hadn't suddenly been transmuted into illegal death rays.

But basic laser pointers are easy to find now. Here's one at Altronics, here's one at Jaycar (Jaycar have several other options, too).

[There are cheaper pointers on eBay, from sellers who at least say they're in Australia, which means they shouldn't be sending your purchase through Australian Customs to be confiscated by our ever-vigilant protectors. People may still be selling cheap pointers at the markets, too. If you believe price equals quality, on the other hand, note that the writhing transporter-accident creature that absorbed both Dick Smith Electronics and Tandy (Radio Shack) in Australia will be pleased to sell you a keychain pointer for $36.98 - at "DSE" here and at "Tandy" here!]

Altronics and Jaycar both want $AU14.95 for a bloody keychain pointer, which is of course a frankly insulting price. For little more than twice that much at current exchange rates a nice man in China will sell you a whole non-contact infrared thermometer, that incorporates an aiming laser. But which I'm sure will whistle through Australian Customs, just like all of the "laser-guided" circular saws, ultrasonic distance measurers, scissors, et cetera.

I chose not to choose a $15 keychain laser. I chose something else.

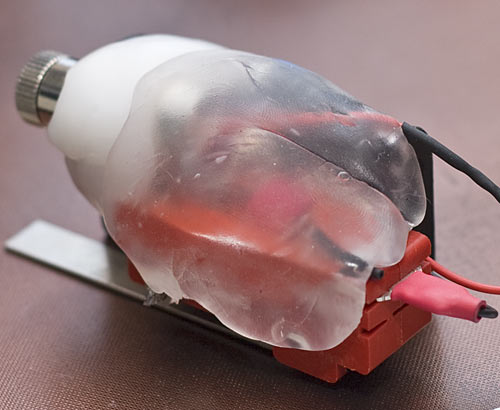

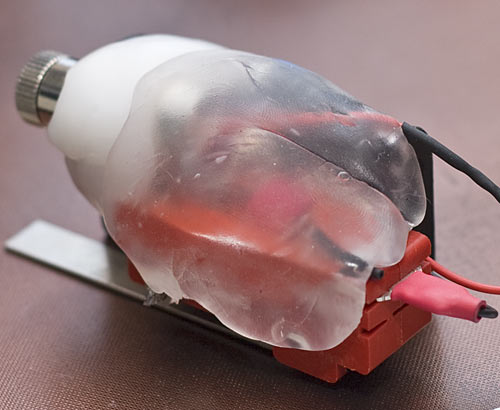

This prison-shiv of a laser pointer...

...took a lot longer to photograph than it did to make.

It's pleasingly bright at around 25mA current - much brighter than your standard button-cell cheapie, but not bright enough to pose any real eye hazard. It has an egg-like shape that feels good in the right hand, with a nice clicky steel switch-bar under the thumb. It has adjustable focus, so you can widen the light out into a splodge of quantum speckle at will. And it had a total parts cost about the same as the abovementioned stupidly-expensive keychain lasers. You could easily make something similar for less than $10, including the two AA batteries.

(It's quite hard to find laser pointers that take AA batteries, these days. Those little button-cell pointers are churned out by the zillion, and many pen-shaped pointers use a couple of AAAs - but if you want the substantially higher capacity-per-dollar of AA power, I think you may have to assemble your own pointer. Or, at least, hack bigger batteries onto a smaller pointer.)

The key component in a do-it-yourself laser pointer is a laser diode, lens and heat-sink assembly - commonly referred to as a laser "module", or "package".

Well, that's the key component unless your DIY ethic requires you to build the module from scratch, as well.

(The state of the DIY art has not, to my knowledge, yet reached actual home-made laser diodes. It's surprisingly easy to make your own very dim LED, though!)

There's no financial reason to build your own laser module, because you can buy ready-built modules in various shapes and sizes - even in colours other than red - startlingly inexpensively on eBay, or from dealers like DealExtreme. And no, Australian Customs won't confiscate your laser module, either - or, at least, they didn't confiscate any of mine.

Because, like an IR thermometer, a laser module is demonstrably not a laser pointer. And it is laser pointers that are illegal here, don't you know.

(I haven't tried importing a genuinely dangerous high-powered laser module, of the type used in hefty laser "pointers" that were already illegal in Australia before the current ridiculous laws went through. I would make a small wager that you would have no trouble importing such a module at all, though. But don't worry - as we all know, those scary domestic terrorists who we keep being warned about, but who mysteriously never seem to actually commit any acts of terrorism, must be so impotent on account of how they are too dumb to figure out how to connect a multi-watt invisible-beam IR laser module - you know, a laser that's actually dangerous - to a battery.

Ahem.

The question for the non-terroristic cat-toy maker is which of the (very) numerous cheap red laser modules will actually suit your purpose. I am happy to announce that I've done the legwork for you, here, for DealExtreme's range at least. I bought a few of their finest, cheapest red laser modules, and this one, yours for a princely four US dollars and six cents delivered to anywhere in the world, is the one you want.

It's got a nice big sturdy heat-sinking case, it's usefully, though not dangerously, bright from modest power, and it's got the abovementioned adjustable collimating lens, too.

The other components of a DIY laser pointer:

1: Batteries. Two AA alkalines, in this case; feel free to use some other combination if you like. (Three D cells would give you outrageously long run time.)

The batteries you choose determine which...

2: ...resistor you should use in series with the laser module.

Laser diodes, like their older relatives, the LEDs, need some kind of current limiting to prevent them from going into thermal runaway and dying very quickly. Inline resistors are usually the simplest option.

I found that the four-dollar DealExtreme module ran nicely, but not excessively, brightly from two AAs through three 91-ohm resistors in parallel, for an aggregate 30.3 ohms. I couldn't find a roughly-30-ohm resistor for the final assembly, so I used a couple of 16s in series. Small laser diodes draw only tens of milliamps, so little quarter-watt resistors are more than good enough.

If you buy some other laser module, don't just trust the "2-4.5V" or whatever that was listed on the eBay auction, hook it up to two AAs, and kill it. You'll need to put a multimeter in milliamps mode - which, remember, has a little resistance of its own - in series with the module and fiddle with batteries and, initially, larger resistance values, to find a suitable value. (That's how I ended up with three 91s in parallel - I started with one 91-ohm, which gave a very dim beam, then put another one in parallel, et cetera.)

The quick and dirty way to figure this stuff out for a laser module of unknown provenance is by starting with resistor values that're clearly much too high - by themselves, across the power supply, they'll let much less than the module's rated current flow - or by using a bench power supply that lets you limit voltage and current. Then you reduce the resistor value (or gingerly wind up the current knob) until the dot stops getting noticeably brighter. Wind it back a bit from that point and you should have a safe value. Or just stop when the dot's still getting brighter with more current, if it's already bright enough for your purpose.

Or you can, of course, sidestep all of this and just buy that DX module, and run it from two series 1.5-volt cells and about 30 ohms.

3: A battery holder. Little black plastic holders like the one I used are almost free on eBay, or you can bodge something up yourself. (Thumb-tacks make good battery contacts, by the way.)

4: A switch. I used a microswitch I had sitting around, which gives a pleasing tactile feel. Any old switch will do, though. Momentary, like my microswitch, if you want the usual hold-down-the-button kind of laser pointer, or standard "unbiased" if you want a pointer that stays on by itself.

(For about the same almost-free price as a black plastic AA-battery holders, you can get a black plastic AA-battery holder with an unbiased switch built in.)

5: Stuff to hold it all together. Solder and glue, for a more professional result; tape and positive thoughts, for a less professional one.

The weird organic-looking white stuff on my pointer is a couple of blobs of polycaprolactone plastic, about which I must digress, because it's brilliant stuff.

At room temperature, polycaprolactone is a tough white plastic, like nylon. But above about 60°C it becomes a pliable, bouncy, transparent putty-like material.

(This is the laser assembly before the second blob of polycaprolactone had fully cooled. It'd be fun if it stayed like that, but you can't have everything.)

You take polycaprolactone granules, and you put them in boiling water, and they turn clear and stick to each other. Just stirring the growing blob around a bit will pick up any loose pellets. Then you fish the spongy blob out and squeeze the hot water out (a slightly painful procedure), and then form the blob to suit your task, usually by just sticking it onto something and squeezing it into shape. Hot polycaprolactone sticks well to all sorts of surfaces, but not so well that you can't peel it off if you make a mistake. And you won't get scalded while doing this, because unlike water, the plastic is lousy at transferring heat to your fingers.

(If you heat polycaprolactone above 100°C, by, for instance, microwaving it instead of putting it in water, it apparently becomes a lot stickier, as well as much more able to burn you. So you might want to leave those higher temperatures to the rapid fabricators. I needed to smooth a little bit of my polycaprolactone blobs, so I wafted a small butane flame past the plastic. But then I smoothed it over with a damp screwdriver, instead of my finger.)

As polycaprolactone cools, it clouds up and stiffens, but does not appreciably shrink. If you haven't gotten your new plastic part shaped right before this happens, just pop it back in the water to re-soften. It's easier to re-shape polycaprolactone than it is to shape it in the first place, because there's less water to squeeze out. You can re-heat the plastic as many times as you like, too, and any excess can go back in the bag for later.

Polycaprolactone in the molecular weights that make it behave in this useful way is manufactured in vast quantities by at least two companies, Solvay and Dow Chemical. Which is great to know if you need a ton of the stuff, but not so much if you just want to replace a missing knob on a radio. (That was my first polycaprolactone project. It worked beautifully.)

Other companies repackage polycaprolactone in smaller quantities at large markups. "Polymorph", "ShapeLock" and "Friendly Plastic" are all polycaprolactone. The first two are very much the same; Friendly Plastic comes in a white-pellets version too, but is also available in a wide range of more-expensive coloured versions. You can colour polycaprolactone yourself, but if you need even, repeatable hues and/or metallic effects, and you don't need a huge amount of the stuff, then you'd probably do better just buying Friendly Plastic.

(The bone-white version is of course preferable, if you want to make creepy biomechanical thingummies.)

If you're in Australia and you just want to see what polycaprolactone is like, get yourself a hundred grams of "Polymorph" from Jaycar for $AU11.50. (Plus delivery, if you buy it online rather than over the counter.) That may go a surprisingly long way; I didn't weigh the Polymorph that went into my laser pointer, but judging by volume it was probably no more than 25 grams.

If you're in the States, there are lots of retail polycaprolactone sources. Try the Maker Shed.

If you're outside the States and want a larger, but not vast, amount of the stuff, many companies stand ready to rip you off.

You can place an international order at Shapelock.com and pay for it, with a pleasingly low shipping fee - and then they'll refund your money, because they don't actually ship overseas. And then they'll tell you to order from Jameco instead. Jameco's international shipping fees aren't mentioned on their site; you can place an order and give your payment info and wait for the delightful surprise, or you can e-mail them, whereupon they will inform you that their cheapest price to send a $US24.95 half-kilo of Shapelock to Australia is $US39.

Sorry. Just had to get that out of my system.

OK, here's how people outside the States - and possibly inside, actually, depending on how all the prices shake out - can buy polycaprolactone at a non-stupid price. Go to this eBay dealer in the UK (on ebay.com, on ebay.co.uk), who's currently on holiday until the 8th and has invisibilised their auctions, but will actually still let you place an order via this listing. They'll sell you 500 grams of Polymorph-branded polycaprolactone for £9.50 plus quite reasonable delivery, with a microscopic discount for multiple half-kilos.

[UPDATE: As pointed out in the comments below, that eBay dealer has a separate Web site too, from which you can download a great PDF about what you can do with Polymorph.]

To make sure I get my order in before all of y'all, I just ordered a key, man, for a total of £32.75 delivered to Australia. That's about $AU54.20, or $US49.80, as I write this.

A kilogram of polycaprolactone is quite a lot - especially when you consider the near-infinite reuseability of the stuff. Unless I suddenly start building sizeable structures, I don't anticipate having to buy any more for some years.

Jaycar offer discounts for bulk purchase, but a kilogram of Polymorph from them is still $AU89.50 ex delivery. So the eBayer in the UK looks like a good deal.

Hm. This post started out being about making a laser, and ended up about making freeform plastic bones. Eh - it'll do.

Do feel free to discuss either subject in the comments!